Threaded rod stud bolts are essential components in a variety of construction, engineering, and industrial applications, providing versatile and reliable fastening solutions. These fasteners, which feature continuous threading along their length, are used in numerous projects that demand high structural integrity and secure connections. This article explores the key features, benefits, and common uses of threaded rod stud bolts, emphasizing their role in enhancing stability and strength in various settings.

What Are Threaded Rod Stud Bolts?

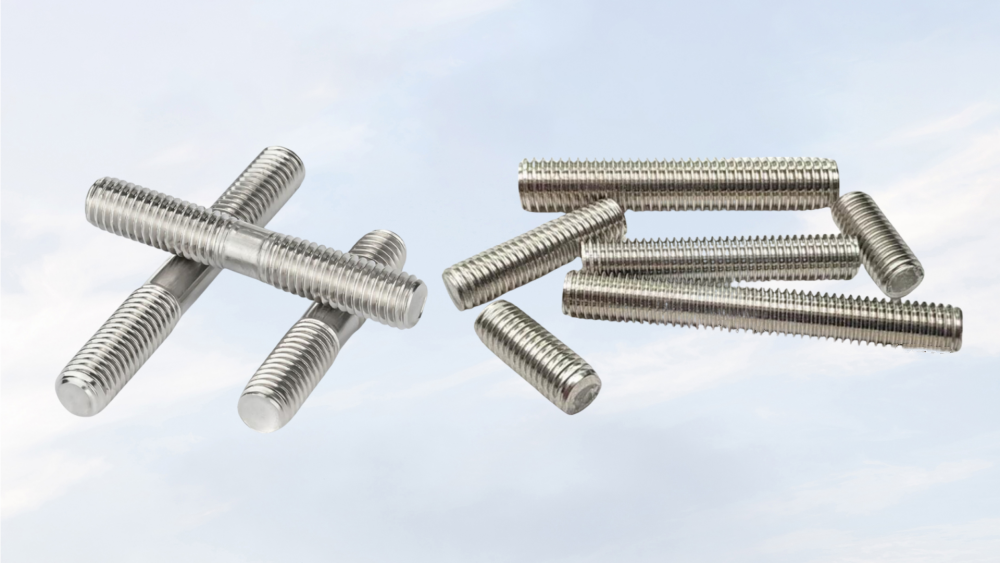

Threaded rod stud bolts are long, cylindrical rods made from high-strength materials, with threads running along their entire length. Unlike traditional bolts that have threads on only one part of the shaft, threaded rods are fully threaded, allowing for greater flexibility in applications where precise length adjustments and secure fastening are necessary. The threaded ends of the rods allow them to be used with nuts or other fastening devices, making them versatile for different uses in construction, industrial, and mechanical settings.

Key Features of Threaded Rod Stud Bolts

1. Full-Length Threading

One of the primary features of threaded rod stud bolts is their continuous threading. This feature allows them to be used in a wide variety of applications, as they can be easily adjusted to the required length and provide a strong, consistent grip throughout their length.

2. High Strength and Durability

Threaded rods are often made from materials such as stainless steel, carbon steel, or alloy steel, offering excellent tensile strength and resistance to corrosion. These high-strength materials ensure that threaded rod stud bolts can withstand significant forces and harsh environments, making them ideal for structural applications.

3. Versatility

Threaded rods can be cut to length, allowing for customizable applications. They can be paired with different types of nuts, washers, or other components, depending on the needs of the project. This adaptability makes threaded rod stud bolts a preferred solution for a wide range of industries.

4. Corrosion Resistance

Many threaded rod stud bolts are made from corrosion-resistant materials such as stainless steel or are coated with protective layers, making them suitable for use in harsh environments, including exposure to moisture, chemicals, and extreme temperatures.

5. Cost-Effective

Threaded rod stud bolts are relatively inexpensive compared to other fastening solutions, making them a cost-effective option for large-scale construction projects, industrial applications, and repairs. Their durability and versatility ensure that they offer value over time.

6. Easy Installation and Adjustment

Threaded rod stud bolts are easy to install and adjust, which makes them a convenient choice for projects that require precise length adjustments or disassembly. The continuous threading allows for quick and secure fastening, reducing installation time and labor costs.

Applications of Threaded Rod Stud Bolts

1. Construction and Structural Projects

Threaded rod stud bolts are widely used in construction and structural applications, including securing beams, columns, and other heavy-duty components. Their high strength ensures that they can withstand significant loads and provide stability to large structures such as bridges, buildings, and towers.

2. Mechanical and Industrial Applications

In mechanical and industrial settings, threaded rod stud bolts are used to secure machinery, engines, and heavy equipment. They are particularly useful in applications that require adjustable lengths or the ability to withstand vibration and movement.

3. Electrical Systems

Threaded rods are often used in electrical systems to secure and support components like conduit, electrical panels, and support brackets. Their corrosion resistance ensures that they can withstand exposure to moisture or chemicals, making them ideal for outdoor or industrial electrical installations.

4. HVAC Systems

Threaded rods are commonly used in heating, ventilation, and air conditioning (HVAC) systems to support ducts, pipes, and other equipment. The rods are used to suspend these components from ceilings or walls, ensuring that they remain secure during operation.

5. Marine and Offshore Applications

Due to their resistance to corrosion, threaded rod stud bolts are commonly used in marine and offshore applications, such as shipbuilding and offshore oil rigs. These fasteners help to secure various components and structures that are exposed to harsh sea environments.

6. Automotive and Aerospace

Threaded rods are used in automotive and aerospace industries for applications requiring high strength and durability. These rods are often used in engine assemblies, chassis, and other critical components that require secure fastening and the ability to withstand vibrations and other stresses.

7. Furniture and Home Improvement

Threaded rod stud bolts are also used in the furniture industry and for home improvement projects. They are commonly used to assemble furniture, support heavy fixtures, or attach components that require additional stability and strength.

Benefits of Threaded Rod Stud Bolts

1. Enhanced Structural Integrity

Threaded rod stud bolts offer strong, secure fastening that enhances the structural integrity of a wide variety of applications. Whether used in construction, mechanical, or industrial settings, these bolts provide the necessary strength to support heavy loads and ensure long-term stability.

2. Customizable Length

One of the biggest advantages of threaded rod stud bolts is their customizable length. They can be cut to the desired size, making them suitable for projects with varying requirements. This flexibility ensures that threaded rods can be adapted to different applications, offering both practicality and precision.

3. Strong Load-Bearing Capacity

Threaded rods are designed to bear significant loads, which makes them ideal for use in heavy-duty construction and industrial projects. The full-length threading allows for an even distribution of pressure, ensuring a secure connection that can withstand mechanical stresses and weight.

4. Resistance to Environmental Factors

The use of corrosion-resistant materials or coatings allows threaded rod stud bolts to perform well in challenging environments, such as exposure to moisture, chemicals, and extreme temperatures. This resistance helps to maintain their strength and functionality over time, ensuring long-lasting performance.

5. Easy to Install and Maintain

Threaded rod stud bolts are easy to install, adjust, and maintain. Their continuous threading allows for quick, secure fastening, and they can be disassembled and reused if necessary. This makes them an efficient solution for applications that require frequent maintenance or adjustments.

6. Cost-Effective Solution

Threaded rod stud bolts are a cost-effective solution for a wide range of applications. Their low material cost, combined with their strength, durability, and versatility, makes them a preferred choice for both small-scale and large-scale projects.

Conclusion

Threaded rod stud bolts are a versatile and reliable fastening solution for applications that demand high strength, durability, and structural integrity. Their continuous threading, customizable lengths, and resistance to corrosion make them ideal for use in a variety of industries, including construction, mechanical, electrical, and aerospace applications. With their ability to provide secure, long-lasting connections, threaded rod stud bolts are an essential component in maintaining the stability and performance of complex systems and structures. By understanding their key features, benefits, and applications, you can make informed decisions when selecting threaded rod stud bolts for your next project.